Specialty Fasteners

What are specialty fasteners?

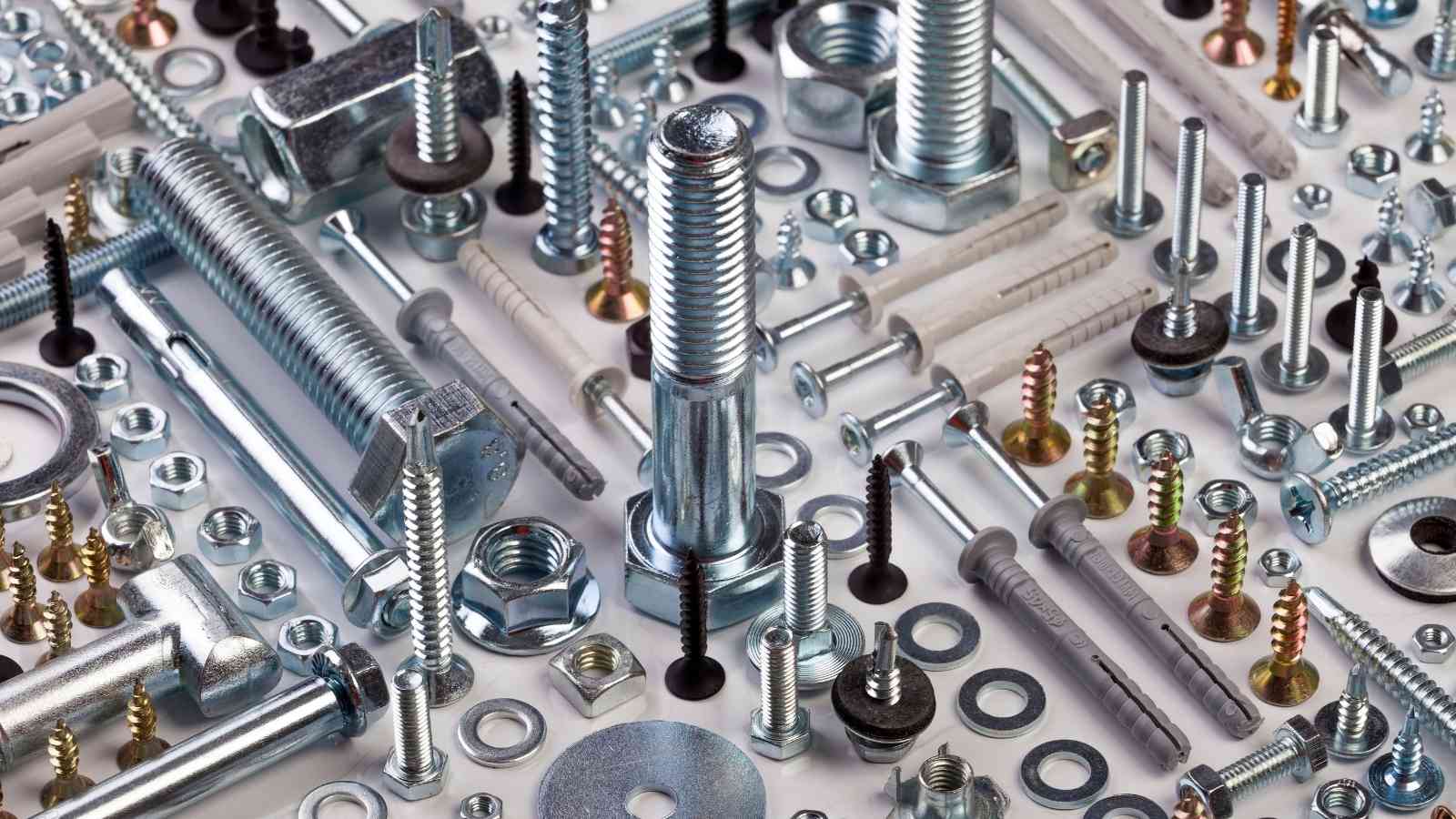

Types of specialty fasteners

Materials used in specialty fasteners

Specialty Fasteners

Applications for specialty fasteners

Specialty fasteners have a broad range of applications, depending on the required strength and corrosion resistance. They are often used to join two or more pieces of material together, but can also be used as nuts, bolts and screws for machinery parts, electronics and medical devices. They are also suitable for outdoor applications and provide superior protection against weathering, saltwater exposure and even extreme temperatures. In addition to this, specialty fasteners are often used in furniture manufacturing in order to hold components securely together without any visible nails or screws present.

Benefits of using specialty fasteners

One of the most significant benefits of using specialty fasteners is their corrosion resistance. This factor is especially useful for outdoor applications, as the fasteners will be able to offer improved corrosion resistance and weather protection than standard fasteners. Specialty fasteners also tend to have a greater strength compared to regular fasteners, providing a diploma of additional protection against wear and tear, deformation and impact damage. Finally, specialty fasteners are often used in small-scale applications, due to their precise dimensions and easy installation requirements.