Fastener Inventory: Eliminate Stockouts Without Overbuying

Fastener inventory management can make or break a production schedule, even though fasteners are often the lowest-cost items on the bill of materials. Done well, it eliminates stockouts, reduces overbuying, and frees your team from chasing “nuts and bolts” so they can focus on higher-value work.

Fastener Inventory Management 101: How to Eliminate Stockouts Without Overbuying

Fastener inventory management is the discipline of making sure the right screws, bolts, nuts, and washers are in the right place at the right time – without tying up unnecessary cash in excess stock. When fasteners are handled casually, they tend to create disproportionate risk because a missing five-cent part can shut down an entire production line.

This article walks through why stockouts are so painful, why overbuying is so common, and how a structured, data-driven vendor managed inventory (VMI) program can help you eliminate stockouts without overstuffing your storeroom.

Why Fastener Stockouts Hurt More Than You Think

When a critical fastener is missing, everything else stops. Operators wait, supervisors scramble, buyers expedite, and shipping dates slip – all because one small item isn’t on the shelf.

Beyond the obvious downtime, stockouts drive a long list of hidden “soft costs”:

-

Extra time spent sourcing and expediting emergency orders.

-

Premium freight to get parts in overnight.

-

Overtime labor and rescheduling to catch up on past-due jobs.

-

Administrative effort in purchasing, receiving, and accounts payable.

Manufacturers have realized that these soft costs related to sourcing, purchasing, expediting, receiving, stocking, and paying for inventory often exceed the value of the fasteners themselves. That is why treating fastener inventory management as a strategic process – rather than an afterthought – pays off quickly.

Common Fastener Inventory Problems: Overbuying, Overstock, and Obsolete Parts

In trying to avoid stockouts, many plants swing to the other extreme: they overbuy fasteners “just in case.” The result is a stockroom full of boxes that no one wants to touch because they may be obsolete, mislabeled, or no longer associated with active parts.

Typical pain points include:

-

Overstocked bins with no visibility into true usage or inventory turns.

-

Multiple, similar part numbers (slightly different finishes or head styles) accumulating over years.

-

Manual spreadsheets or clipboards are used to manage bin levels and kanban cards.

-

No clear ownership of fastener replenishment across departments.

Without good data and clear responsibility, teams revert to habit: “order extra so we never run out.” This approach ties up cash, consumes space, and still fails to guarantee product availability

How a Fastener Vendor Managed Inventory (VMI) System Works

A fastener vendor managed inventory (VMI) system changes the model by shifting responsibility for planning and replenishment to a specialized partner. Instead of guessing when to reorder, your VMI provider monitors usage, adjusts stocking levels, and schedules releases so you always have what you need – and not much more.

Blue Chip Engineered Products applies a Solve. Source. Schedule. Service. approach to inventory management, built around a detailed, step-by-step plan tailored to each customer’s departments and goals. The core idea is simple:

-

Solve: Understand current problems and constraints in purchasing, engineering, quality, and production.

-

Source: Determine the best way to supply each fastener or assembly, including special cold-headed parts and complex components.

-

Schedule: Set up release schedules and stocking strategies that align with your manufacturing demand.

-

Service: Continuously monitor, adjust, and support the program to ensure it continues to deliver savings and reliability over time.

With VMI, you move from reactive ordering to a proactive system that uses real data and defined processes to manage fastener inventory.

Using Scales, RFID, and Bar-Coded Containers to Prevent Stockouts

Technology, instead of clipboards, powers the most effective VMI programs.

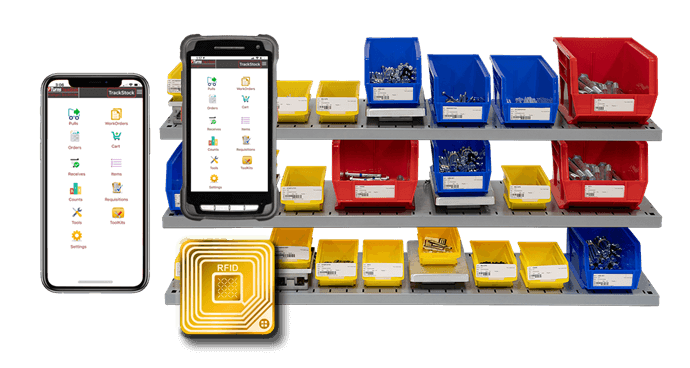

Blue Chip’s system uses electronic scales, RFID, and wireless technologies to track inventory in real time and trigger replenishment before you hit a critical low.

Key elements include:

-

Electronic scales and RFID: Bins or containers sit on scales or carry RFID tags that communicate quantity or status to data-driven software.

-

Bar-coded containers: All parts are stored in bar-coded containers for clear identification, with labels that may include quantity, part number, description, and color coding for different areas or lines.

-

Inventory tracking and reporting: The system provides reports by part number, and projected needs based on historical usage, helping you understand what you actually consume and when.

This combination of real-time data and historical trends allows the VMI provider to maintain the “right amount of inventory” so you have peace of mind that stockouts will not occur – without padding every bin to the ceiling.

Right-Sizing Fastener Inventory Levels Without Risking Downtime

Eliminating stockouts is only half of the equation; the other half is right-sizing inventory so cash is not trapped in unnecessary stock. That starts with using your previous and projected usage history to determine appropriate inventory levels for each part.

A structured fastener VMI program will typically:

-

Analyze historical consumption and manufacturing schedules to set rational min/max levels for each fastener.

-

Align stocking quantities with your production releases so inventory is built and held ahead of demand, but not excessively.

-

Use blanket purchase agreements and centralized stocking so the product is available for release on your schedule without long lead times.

By controlling the process from order through manufacturing to flexible release scheduling, Blue Chip reduces both your time spent on logistics and your total inventory investment while guaranteeing product availability.

Beyond Nuts and Bolts: Kitting, Global Sourcing, and Value-Added Services

Fastener inventory management is not just about individual SKUs; it also covers how those parts arrive at the line and are sourced. A strong partner can streamline this through kitting, global sourcing, and quality assurance.

Some examples:

-

Global sourcing: Blue Chip partners with reliable domestic and overseas factories to provide quality products – often with significant savings – while handling letters of credit, broker fees, duties, and quoting in U.S. dollars. This keeps your team out of international logistics while capturing cost advantages.

-

Kitting and packaging: Fasteners can arrive as hardware kits built with multiple parts or single-part packs, with automated packaging that includes your logo, barcodes, and data matrix codes, plus inserted instruction sheets where needed.

-

Inspection and quality control: Parts are inspected to current drawings or applicable standards before packaging and shipping, ensuring conformity before they ever reach your floor.

These value-added services further reduce soft costs by simplifying assembly, minimizing errors, and tying inventory management directly into your quality and engineering requirements.

When to Consider a Fastener VMI Program for Your Plant

Not every operation needs a fully managed program, but certain warning signs suggest that a fastener VMI solution will deliver quick returns.

You should consider VMI if:

-

You experience recurring fastener stockouts or frequent expediting.

-

Buyers spend disproportionate time cutting POs for small hardware.

-

Your stockroom is crowded with unknown or obsolete fastener inventory.

-

You lack clear visibility into true annual usage or inventory turns per part.

-

Coordinating fasteners across multiple plants or locations is a constant headache.

A good starting point is a simple internal review: for your top fastener SKUs, can you easily see annual usage, current on-hand quantity, and the number of emergency orders placed in the last year? If not, a more structured, data-driven approach is likely to pay off.

See How Blue Chip’s VMI Eliminates Stockouts and Cuts Soft Costs

Fastener inventory management does not have to be a constant fire drill or a guessing game. With a well-designed VMI program, you can eliminate stockouts, reduce overbuying, cut soft costs, and give your team confidence that the right parts will be at the line when they are needed

To see how Blue Chip Engineered Products implements its Solve. Source. Schedule. Service. approach – including electronic scales, RFID, bar-coded containers, and tailored inventory plans – visit the Vendor-Managed Inventory page at https://www.bcepi.com/vendor-managed-inventory.