RFID and Wireless Technology in Vendor Managed Inventory

RFID and Wireless Technology in VMI: Ensuring No Stock-Outs

In today's competitive manufacturing landscape, inventory automation is vital for operational efficiency and profitability. For engineers, purchasing managers, and supply chain professionals, achieving optimal inventory levels in complex fastener supply chains means more than just accuracy—it’s about confidence and continuity.

Traditional methods frequently fall short: time-consuming counts, costly stock-outs, and excessive overhead slow progress and erode margins.

Vendor Managed Inventory (VMI), when delivered by an ISO-certified supplier such as Blue Chip Engineered Products, brings a new standard of reliability to the supply process. Enhanced with RFID and wireless technology, Blue Chip’s VMI system ensures fastener availability, delivers data-driven insights, and eliminates traditional inventory headaches.

How RFID and Wireless Technology Work in Blue Chip's VMI

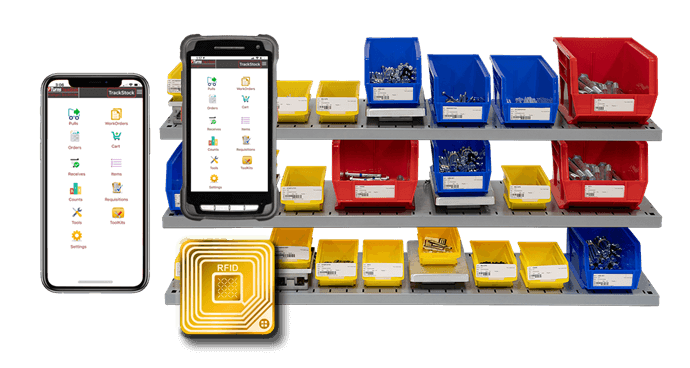

RFID (Radio Frequency Identification) and wireless technologies form the technological backbone of Blue Chip’s VMI program. These innovations replace error-prone manual processes with automated, real-time data collection. RFID tags, unlike traditional barcodes, can be read remotely and in bulk, supporting efficient, hands-free tracking of thousands of fastener SKUs.

Leveraging electronic scales integrated with wireless systems, Blue Chip’s warehouse management solution automatically tracks part consumption. RFID readers update fastener inventory in real time as components are removed from bins for production. This wireless data transmission, supported by data-driven software, eliminates delays in inventory reporting and provides immediate visibility across all customer locations.

Electronic inventory controls ensure proactive replenishment: as fasteners reach min levels, reorders are triggered automatically based on historical usage patterns and projected needs. The result is a seamless flow of product to the shop floor—without interruptions due to stock-outs.

Benefits of RFID and Wireless-Tech VMI from an ISO Certified Supplier

The benefits realized in Blue Chip’s ISO-certified VMI program extend beyond basic accuracy. Real-time inventory visibility means engineers always know what’s available for current and upcoming projects. Purchasing professionals streamline their operations, freeing up time from manual counts and chasing parts to focus on strategic sourcing. With RFID and barcode tracking, full traceability is maintained—meeting compliance and quality standards required by regulated industries.

Supply chain managers gain enhanced supply chain visibility and control, with automated reports for every part, consolidated billing, and predictive analytics based on historical fastener usage. Inventory investment is reduced by 20–30%, stock-outs become a thing of the past, and overhead is slashed—all while meeting ISO 9001:2015 quality requirements.

Solving Inventory Management Challenges Through Blue Chip’s Vendor Managed Inventory

Manual inventory management is labor-intensive and fraught with error. Stock-outs can delay production, while overstocking ties up precious resources. Blue Chip addresses these pain points directly: RFID and wireless tech, combined with barcoded containers and color coding (for area identification), create a layered, resilient inventory solution for engineers and buyers alike.

Advanced tracking enables precise demand forecasting and rapid response when patterns shift. For regulated industries, Blue Chip’s ISO certification guarantees parts meet specifications and are reliably tracked from receipt to shipment. Their technology-driven VMI system eliminates manual bottlenecks, transforming inventory management into a value-added process for all stakeholders.

Implementing VMI with Blue Chip: A Step-by-Step Approach

Blue Chip Engineered Products approaches each Vendor Managed Inventory roll-out with detailed customization for every client. The process begins with thorough analysis of historical consumption, inventory turnover, and unique operational requirements. RFID readers and wireless infrastructure are deployed at critical locations, integrated with company ERP platforms for seamless data flow and reporting.

Barcoding augments the RFID system, providing redundant checks and compatibility for warehouse teams. Blue Chip works closely with purchasing, engineering, and quality teams to tailor release schedules, packaging, and logistics—minimizing soft costs while enhancing reliability and traceability. Training ensures your team can smoothly transition and maximize ROI, with support every step of the way.

ISO Certification: Quality, Reliability, Compliance

Choosing an ISO certified fastener supplier as your VMI partner has clear advantages. ISO standards demand documented procedures, rigorous quality controls, and systematic traceability—making Blue Chip Engineered Products the trusted choice for critical applications. Customers benefit from peace of mind, knowing every fastener is supplied, tracked, and replenished to international quality benchmarks.

Maximizing ROI Through Strategic VMI Implementation

RFID-powered VMI with Blue Chip isn’t just about reducing costs—it's about elevating quality and responsiveness. Production runs smoother, downtime is eliminated, and supplier relationships are strengthened. Better demand forecasting protects your margins and keeps your lines moving, even when market conditions fluctuate. Every improvement is secured by ISO compliance and robust data analytics.

RFID and wireless technology, delivered through an ISO-certified fastener supplier like Blue Chip Engineered Products, redefines inventory management for engineers, buyers, and supply chain specialists. If readiness, reliability, and compliance matter to your operation—consider the proven results of Blue Chip’s VMI system.

Discover how Blue Chip can eliminate waste, guarantee product availability, and reduce labor, inventory, and overhead with Solve. Source. Schedule. Service.

Visit https://www.bcepi.com/vendor-managed-inventory for more information on industry-leading inventory optimization