The True Cost of a Purchase Order: Exploring Vendor Managed Inventory

In the intricate procurement and supply chain management world, issuing a purchase order (PO) might seem straightforward. However, beneath the surface lies a web of complexities that contribute to what is known as "the true cost of a purchase order." In this article, we'll delve into the various steps involved in issuing a purchase order and shed light on a more efficient alternative - Vendor Managed Inventory (VMI).

Understanding the Purchase Order Process

- Identifying Need: The process begins with identifying the need for goods or services. This can arise from various sources, such as inventory depletion, new projects, or customer orders.

- Requisition: The next step involves creating a requisition detailing the items required, quantity, and desired delivery date. This requisition is then sent for approval from relevant departments.

- Supplier Selection: Once approved, the procurement team selects a suitable supplier. This decision is based on factors like cost, quality, lead time, and supplier reliability.

- Negotiation: Negotiations with the chosen supplier are carried out to finalize terms, pricing, and other conditions.

- Purchase Order Creation: The purchase order is generated with the agreed-upon terms. This document outlines the specifics of the order and acts as a legally binding contract between the buyer and the supplier.

- Order Confirmation: The supplier acknowledges the order and confirms the delivery timeline.

- Goods Shipment: The supplier ships the ordered goods and the required documentation, such as packing slips and invoices.

- Goods Receipt and Inspection: The buyer's team inspects the goods for quality and quantity compliance upon delivery. Any discrepancies or issues must be addressed, leading to potential delays.

- Invoice Processing and Payment: The supplier sends an invoice that must be verified against the purchase order and the received goods. After verification, payment is processed.

- Record Keeping: All relevant documents and records related to the purchase order must be maintained for future reference and audits.

The Hidden Costs of Purchase Orders

While purchase orders are essential for maintaining control and accountability in the procurement process, they come with hidden costs that can impact efficiency and profitability:

- Administrative Costs: The entire PO process requires significant administrative effort, from requisition creation to documentation maintenance.

- Lead Time: The time taken from identifying the need to receive the goods can be considerable, affecting operational agility.

- Error Resolution: Discrepancies in goods received, invoices, or terms require additional time and resources to resolve.

- Inventory Holding Costs: Traditional PO processes might lead to overstocking or stockouts, both of which incur costs.

- Communication Delays: Communication gaps between departments and suppliers can lead to delays and misunderstandings.

Vendor Managed Inventory (VMI) as an Alternative Approach

Vendor Managed Inventory presents a proactive solution to address the challenges associated with traditional purchase orders. In a VMI arrangement:

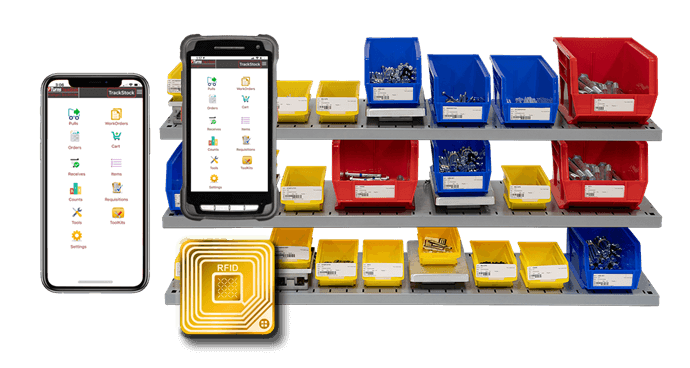

Supplier Responsibility: The supplier takes on a more active role in inventory management. They monitor stock levels and replenish supplies as needed, reducing stockouts.

Continuous Replenishment: VMI enables a continuous flow of goods, reducing the need for repeated purchase orders and their associated administrative overhead.

Shared Data: Both the buyer and the supplier have access to real-time data, fostering better collaboration, accurate demand forecasting, and efficient replenishment.

Reduced Lead Time: With VMI, lead times can be significantly reduced as the supplier maintains a constant presence in the buyer's supply chain.

Cost Efficiency: VMI can lead to lower inventory holding costs, reduced administrative expenses, and minimized errors, ultimately contributing to cost savings.

While the traditional purchase order process is a necessary procurement element, its hidden costs can erode efficiency and profits.

Vendor Managed Inventory emerges as a promising alternative that streamlines the supply chain minimizes administrative burden, and fosters a more collaborative relationship between buyers and suppliers.

By adopting VMI, businesses can unlock a leaner, more responsive, and ultimately more profitable supply chain management strategy.